Industrial Applications of Electrolysis – Purifying of Copper

- Copper is a good electrical conductor and is used extensively to make electrical wiring and components. However, the presence of impurity in copper can reduce its electrical conductivity.

- In industry, electrolysis processed is used to purify copper, and the process is called electrolytic refining.

Electrolytic Refining of Copper

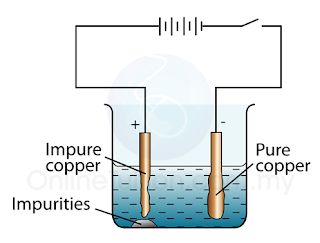

- Figure above shows the illustration of the apparatus setup to investigate electrolytic refining of copper.

- When electricity flows, the copper in the impure anode dissolves in the solution to form copper ions.

- Copper ions are then deposit on the cathode which consist of a piece of pure copper.

- In SPM, you need to know

- the electrolyte used

- the electrode for the impure and pure copper

- the reaction at anode and cathode

Electrolyte:

Copper(II) sulphate

CuSO4 à Cu2++ SO42-

Electrode:

Anode: Impure copper

Cathode: Pure copper

Chemical Reaction

Anode:

Cu —> Cu2+ + 2e

In anode, the copper atoms from the electrode are ionised to form copper(II) ions.

Cathode

Cu2+ —> Cu + 2e

In cathode, the copper ions are discharged to form copper atom and then deposit on the surface of the key

Note: Impurities in the copper do not dissolve, and instead fall off the anode as anode sludge. At the cathode, the copper ions are deposited as pure copper metal.