Industrial Applications of Electrolysis – Electroplating

- Electroplating is a process to coat an object with a thin protective layer of metal

- Electroplating is used to

- prevent corrosion

- improve the appearance of the objects

- In electroplating,

- the anode is the electroplating metal

- the cathode is the object to be electroplated

- the electrolyte must contain the ions of the plating meta

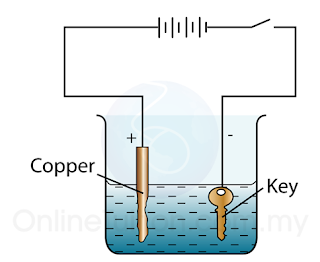

Example: Electroplate a Key with Copper

Electrolyte:

Copper(II) sulphate

CuSO4 —> Cu2+ + SO42-

Electrode:

Anode: Copper

Cathode: Object to be electroplated

Chemical Reaction

Anode:

Cu —> Cu2+ + 2e

In anode, the copper atoms from the electrode are ionised to form copper(II) ions.

Note: The anode is then made of the metal we wish to plate with (copper), and the electrolyte needs to be a solution of a salt of this metal (copper(II) sulphate).

Cathode

Cu2+ —> Cu + 2e

In cathode, the copper ions are discharged to form copper atom and then deposit on the surface of the key

Note: we need to make the cathode the object for plating